Easy to work with, and I work with in 5ft away from a very large window, so I don't get to inhale any of the hazzardous fumes.Ībout the crystal, I wasn't aware of that and your suggestion is very welcome. It alone would have gained you a job at anyplace I worked at.įirst of all, thank you very much for your remarks. too.īe very proud of that board, You DID an EXCELLENT Job. It is very hazardous to burn FR4 laminate But it is very hard to do. FR4 or fiberglass has one drawback and that is that protective gear should be worn while working with which includes cutting or drilling or especially sanding or filing of the pc-board must be done while wearing a mask and goggles, drilling goggles and a painters mask are all the safety equipment required. De-lam's easily and after all that the material is hygroscopic and a health hazard if burned which includes while drilling it. Certainly not for any of it's outstanding physical attributes like poor strength, poor heat resistance.

The clock will be most accurate over a long term basis if the temperature of the crystal is controlled and the simplest method is to tie the crystal case to the thermal mass of the PCB.

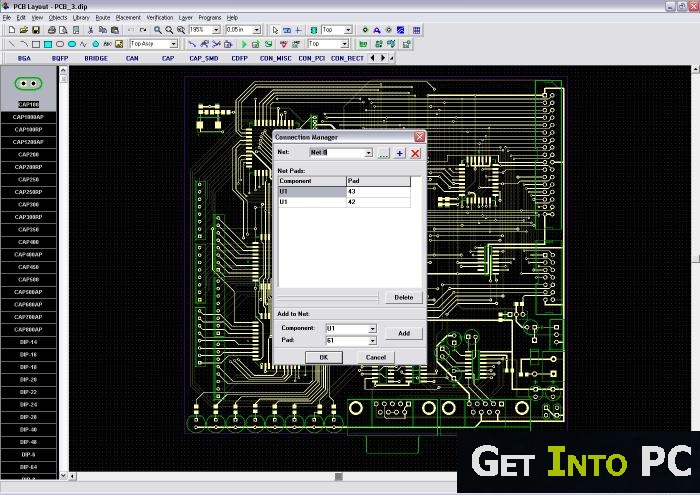

#Create bus diptrace Pc#

One small question first though, Why not put the crystal down close to the pc board and perhaps affix it to the board. I thought I was trying to solder galvanized iron. and I tossed the whole roll, I have Never worked with solder as bad as that. I bought a half pound of the tin stuff, cost me $20+ dollars. I personally think that perhaps I've really used 2 pounds of solder in all the years I've been soldering. Personally I won't use anything but my 60/40 solder. All your joints are consistent in appearance, properly 'filleted' and of lead solder too. Good level soldering and at the right temperature too. Overall a Very nice board and obviously you've practiced a bit. The video below shows how the shield will be ultimately used : The copper was etched in iron perchlorate for 15 minutes. The PCD was designed using Diptrace, printed on cheap magazine paper using a laser printer and then transfered to the copper plane using an iron in its hottest setting for exacty 2'30".

The LCD library is from Adafruit (NewLcdLibrary), and not the stock LCD library.

#Create bus diptrace update#

In the final project I'll be using this EEPROM to store settings (like LCD contrast, update interval, etc), while the Atmel 1Mbit EEPROM will be used to store the data being logged. To work with the DS1624, I modified the library from Federico and Riccardo Galli to add a few more options to it and also to enable R/W from/to the DS1624's built-in EEPROM (256 bytes). I did it this way because other shields may use the Arduino's pins 2 and 3. Red jumper: enable/disables RW on the EEPROM chip.īlue jumpers: enable/disables the interrupts from the DS1337+ in the Arduino's INT0 and INT1 pins. The jumpers have the following functions: The purpose of the project was to create a temperature data logger for the server room I run, using Arduino, and at the same time have an interface that was both efficient and ease to use.Įverything runs on the I 2C bus, which is connected to the UNO's pins A4 and A5. Without the valuable help of users of this forum, this project wouldn't be completed as fast. I'd like to share with you the completion of my first homemade Arduino shield.

0 kommentar(er)

0 kommentar(er)